High efficiency three-way closed impeller:

the application of efficient three-way closed impeller can achieve 6-8% higher efficiency and 6-8% lower energy consumption than the two-way impeller.

Overturning test:

After the impeller is processed, the overturning test is carried out at the rated speed of 110-120% to ensure the safety of the impeller in the field.

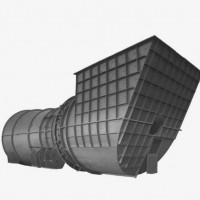

Integral steel base:

The

main engine and gear box adopt integral base design. 100% pre-assembly

shall be carried out in the factory and the pre-assembly position shall

be recorded on the base by positioning pin.

-- Ensure the accuracy and cycle of on-site installation;

-- A startup debugging success;

-- Strong stiffness, offset the uneven settlement of concrete;

-- Concrete foundation construction is simple and the cost is low.

Balance plate design:

Through

the balance plate, the pressure difference between inlet and outlet of

turbine is used to balance the thrust of rotor, reduce the load of

thrust bearing and improve the service life of thrust bearing.

Rotor material:

The

impeller is made of imported high-strength stainless steel, which has

been heat treated for many times during processing to ensure its

strength and corrosion resistance. Stainless steel bushing is used to

prevent corrosion effectively

Tilting tile bearing:

Tilting

tile support bearing + Kingsbury thrust bearing is used to replace

fixed tile. Tilting tile bearing blocks can swing freely with different

speed, load and bearing temperature, and form multiple oil wedges around

the journal. The stability is much higher than that of fixed tile

bearings, and the whole machine runs stably with low vibration.